The factory of the future is being designed at the competence centers

Article by Francesco Profumo, FBK President, for GARR NEWS No. 18, July 2018

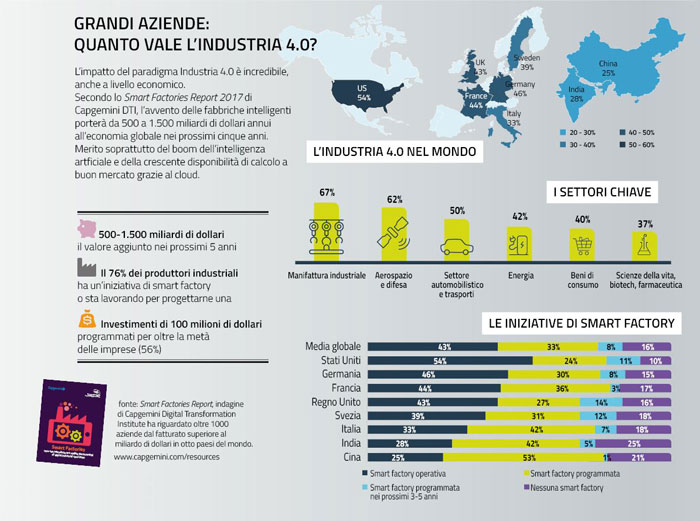

Europe is trying to meet the big challenge of productivity and competitiveness in new industry. The program provides for initiatives at both EU and single country levels. 2018 is an important year as the European Institute of Innovation and Technology (EIT) has launched a major call on the topic of the factory of the future. Proposals will be made with the participation of 6 countries and a competence center will be set up in each country with the aim of designing the industry of the future.

An important factor in future competitiveness will be the ability to produce constructively. We can give a practical example starting from sculpture. Traditionally, you would start from a block of marble, chisel it and obtain a wonderful result, i.e. the sculpture. However, a lot of waste is produced and a lot of energy is put into making this object. If you used marble dust to make a sculpture instead, you could obtain the object following a constructive/additive process. The factory of the future has, with additive manufacturing, precisely this kind of goal. In fact, it starts from dust and, by using a 3D printer, it creates new products, which are designed differently, require 60% less energy to be manfactured, and are lighter.

This is a great challenge, but it is not the only one. In fact, we are increasingly seeing manufacturing that occurs within places where everything analogical is converted into digital and this is obtained by embedding sensors in objects – the Internet of Things, precisely – which provides us with millions of data to be used in improving production processes.

Not only Europe is showing interest in these issues. In fact, in Italy the Ministry of Economic Development has issued a call for tenders for the creation of competence centers, dedicated to three main activities: training, retraining of industry workers and implementation of production processes with new equipment that will be used by companies on an in-service basis.. Only when machines become a critical part of manufacturing processes with people trained to use them, and when prices for these processes drop internally, companies will go to full capacity. The way companies work will change as well as they will increasingly work in a connected manner, making data transmission, and consequently the role of ICT and large infrastructures, such as the GARR network for research and education, more and more strategic. This will become essential to grow together and to modernize a country with valuable skills that could be made available to Industry 4.0.

ARTICLE first PUBLISHED on July 23, 2018 in GARR NEWS N° 18