Attention to safety, high precision, low power: the first products from the Janus project are making it to the market

Social distancing and workplace safety: these are the main applications for businesses and communities that the Janus “two-faced” system, created in the laboratories of the Fondazione Bruno Kessler and the University of Trento, provides.

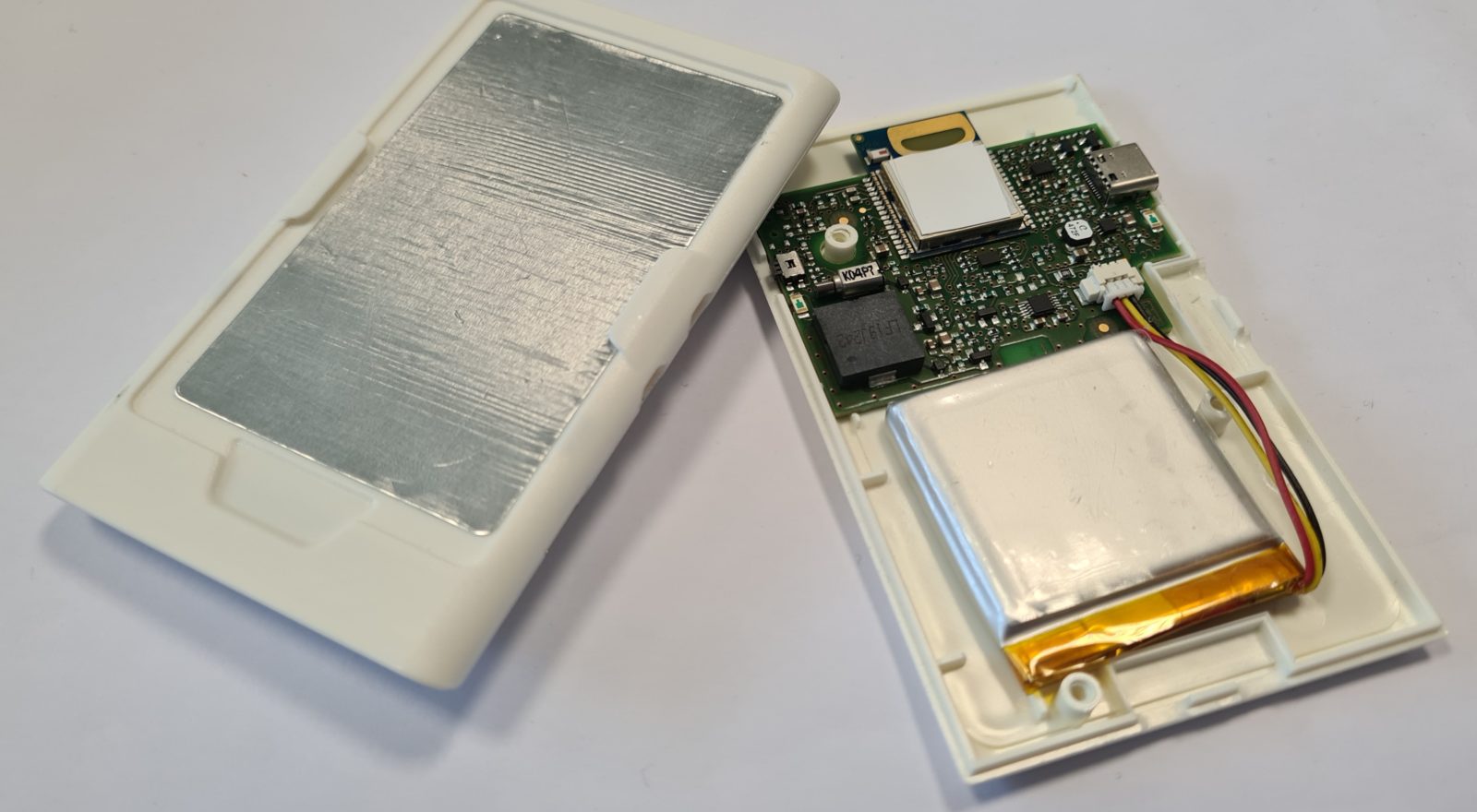

Among the first applications is the efficient automated monitoring system for distancing, the containment measure mandated by the pandemic. When worn, the small device emits vibrations, sounds or lights in the event of risks or violations and transmits information to the wearer and, anonymously, to a control platform. It has already been marketed by the Reply SpA group. Two multinationals in the food and beverage industry are among the first customers.

Increased safety for staff, higher precision in warehouse operations, higher speed, no errors. From Trentino, a big small revolution originated from the laboratories of the Fondazione Bruno Kessler and the Department of Engineering and Information Science of the University of Trento is making it to the market. We are talking about Janus, a next generation system that allows users to monitor in real time, with great accuracy and with low power usage, the distance between devices worn by people or placed on moving machinery or other potentially hazardous objects. This makes it possible to monitor social distancing but also to increase safety at work, reducing risks for people.

Janus devices are wireless, the size of a credit card and extremely precise, and they guarantee power supply for several months thanks to rechargeable batteries. They can easily be worn around the neck, attached to the belt or simply in a wallet. The device detects the position with a margin of error of less than ten centimeters and can send a vibrating, light and/or sound alarm to the control platform. The system respects user’s confidentiality as personal data are not collected. The decision to invest in the development of this technology on an industrial scale was made by Reply SpA, an Italian consulting, system integration, digital services applications company, specializing in the design, implementation and maintenance of Internet and social network solutions.

Janus devices are wireless, the size of a credit card and extremely precise, and they guarantee power supply for several months thanks to rechargeable batteries. They can easily be worn around the neck, attached to the belt or simply in a wallet. The device detects the position with a margin of error of less than ten centimeters and can send a vibrating, light and/or sound alarm to the control platform. The system respects user’s confidentiality as personal data are not collected. The decision to invest in the development of this technology on an industrial scale was made by Reply SpA, an Italian consulting, system integration, digital services applications company, specializing in the design, implementation and maintenance of Internet and social network solutions.

«With this system, companies can find out in real time if their employees are being exposed to risks in the workplace, and maintain compliance with the physical distancing to the end of containing the pandemic. This information is important not only for businesses but also in other places open to the public, such as communities, schools, offices» said Maurizio Griva, senior manager of Concept Reply, hardware and software development partner of the Reply group specializing in innovation applied to the Internet of Things. «The pandemic has had inevitable effects on global supply chains and has forced companies to adapt their operational plans to mitigate the impact of these changes. Janus is a decisive innovation system that aims at making the monitoring of work and personnel safety smoother, safer and more efficient».

The first customers – Among the first Reply SpA customers to decide to use this technology are two large multinationals in the food and beverage industry. The first group is already using the solution for contact identification and tracing and social distancing monitoring in manufacturing plants around the world and factories with hundreds of active tags. Staff wear the badge at the start of the day. This will warn the wearer in case of exceeding the set risk thresholds, through a visual and audible signal. The high detection accuracy prevents false contacts, thus allowing staff to operate safely. The data collected, completely anonymous, are then made available, separately for each plant, in order to reconstruct, if necessary, the chain of contacts. After a first successful experimentation, the customer is considering the extension of the system to other safety needs and procedures unrelated to the pandemic, such as automated anti-collision alarms for interaction with moving machinery.

Same positive experimentation for another multinational in the food sector, which initially introduced the solution for the sole purpose of containing Covid-19 infections within its production plants. But given the accuracy and reliability of the system, they decided to use it on a larger scale for staff safety. More than just personal protective equipment, Janus is seen as a “safety enabler” to contain risk in areas or near hazardous machinery.

Janus: this is how the two-faced revolution works

The key to the Janus system is the combination of two radio technologies. On the one hand, Bluetooth, which is able to determine distance while consuming little battery but with the problem of poor measurement accuracy, with errors that can reach the meters. On the other hand, ultra-wideband (UWB) which reduces distance errors to the centimeters but uses much more power. This explains Gian Pietro Picco, full professor of Information Processing Systems at the Department of Engineering and Information Science and project coordinator, together with Amy Murphy, senior researcher of the E3DA (Energy Efficient Embedded Digital Architectures) unit at Fondazione Bruno Kessler. «There are already systems on the market – take the smartphones that we carry in our pockets – that allow users to estimate distances, which use Bluetooth to exchange messages and information with those around – explains Picco. However, distance estimation in these systems is influenced by environmental factors and leads to possibly gross errors that make these systems unreliable, especially in situations where people’s safety is at stake. So Janus uses Bluetooth only to understand if there are other devices around the user and then, thanks to the UWB radio that uses a more accurate pulse system, estimates the distance with high precision. It is a two-sided system, one for Bluetooth and one for UWB: that’s why we called it Janus, after the Roman god with two faces».

«The uses of Janus and of UWB technology in general are many» Picco adds. “Many have to do with safety in the workplace. Let us consider how important it is to constantly monitor environments with potentially hazardous production lines, such as where harmful materials or moving machinery are present. Also, in these times of pandemic, how useful is timely help in supporting interpersonal safety distances. Not only that: Janus could also make it into our smartphones. iPhone 11 was the first model to also support UWB in addition to Bluetooth, but models from Samsung and others are already on the market».

Janus: from research networks to large business warehouses

Janus’s success on the market is the result of a series of virtuous steps that have the University of Trento and Fondazione Bruno Kessler as the main players. The research project and the drive for innovation originated in the laboratories of the Department of Engineering and Information Science of UniTrento and in the Energy Efficient Embedded Digital Architectures (E3DA) unit at FBK; the prototype was then developed with the support of the Foundation for research enhancement in Trentino (VRT). After receiving further substantial funding from EIT Digital, a large logistics group, Reply SpA, has grasped the business opportunity and has bet on its development on a global scale, bringing home by now the first results in terms of efficiency and competitiveness.

FBK /UniTn/Reply Press realease