3D Metrology in industry

3D optical measurement techniques allow to inspect industrial components for quality control analyses, being very flexible, accurate and, sometimes even low cost

Industry 4.0 is the synergetic convergence of advanced technologies that connect the physical and digital world together, giving birth to a new flexible production ecosystem. Human beings, machine tools, production facilities, logistics and any other component of a self-organized production are interconnected (Internet of Things – IoT) through digital information and communication technologies in all stages of the life cycle of a product. This new production paradigm relies on the integration of Artificial Intelligence (AI), metrology, smart sensors, big data, predictive analysis and dynamic simulations.

Why is 3D metrology more and more important in Industry 4.0?

3D metrology, performed with optical techniques, provides 3D measurement of shape and size with known uncertainty, a key indicator of whether we can use or not the performed measurement for a specific dimensional analysis – says Fabio Menna, senior researcher at the 3DOM unit of FBK’s Center for Digital Industry. Uncertainty, but also traceability, are crucial in many industrial applications, in particular for those complex systems made by assembling several smaller components, each of them accurately manufactured to fit together.

An effective and efficient quality control process is very important in the new manufacturing paradigm of Industry 4.0. 3D metrology in the manufacturing loop provides key information on whether dimensional anomalies and other types of defects are systematic and whether they can be compensated or even corrected in real time. Also, 3D metrology can provide information on the origin of the defects such as for example caused by machine aging and/or wearing, thus taking part in predictive maintenance processes where the analysis of anomalies over time can be predicted to avoid more dangerous failures or even production stops.

Fabio Menna (left) and Fabio Remondino (right) in the 3DOM unit laboratory

3D optical measurement techniques have the advantage of being very flexible, capable of reaching high accuracy even with low cost hardware if proper calibration methods are employed.

In the context of intelligent manufacturing, within the Industry 4.0 production model, the quality control process is also experiencing a transformation towards more flexibility. 3D optical metrology techniques provide an added value throughout the complete production stages empowering faster (even real time) analysis and decision making in design, manufacturing, assembling, inspection and report.

Example of 3D measurements scenario: tire manufacturing where 3D metrology is performed in real time to assist retreading processes.

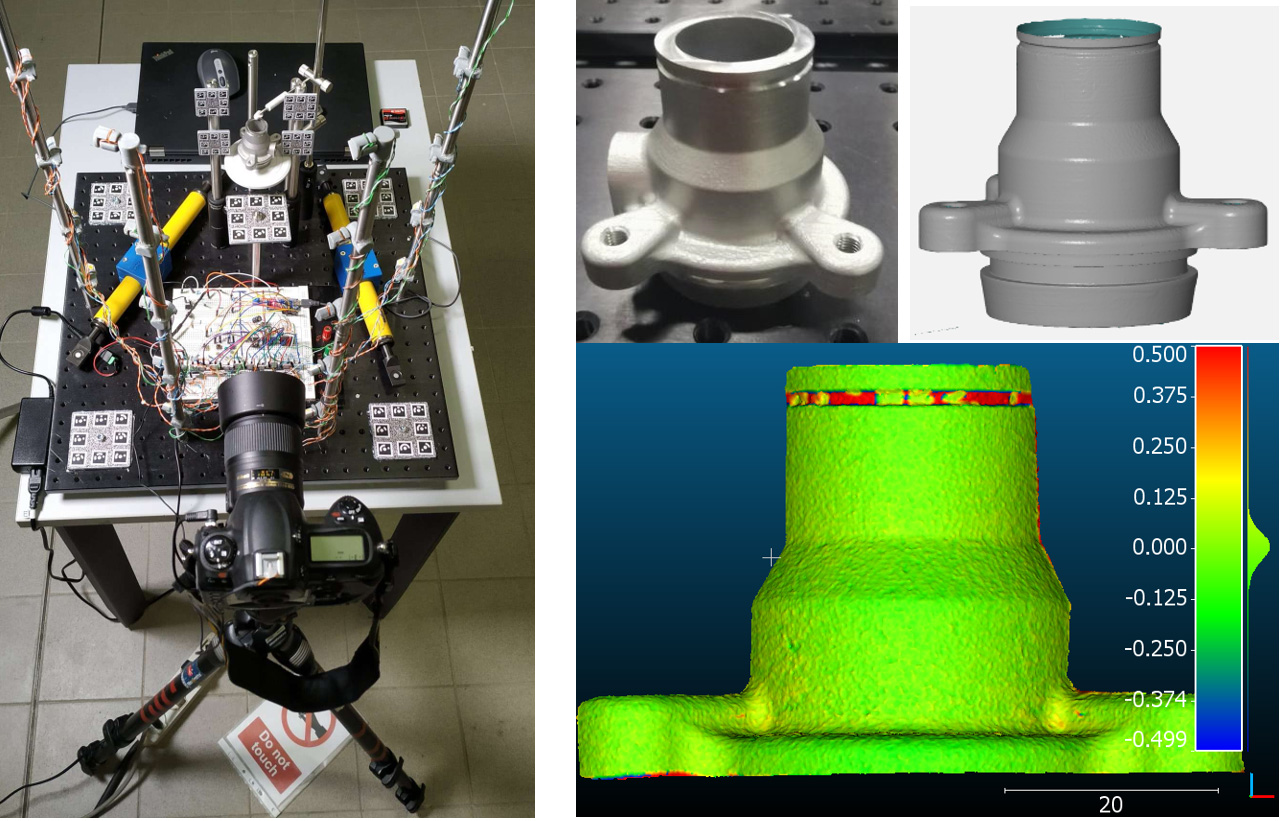

For more than ten years – continues Fabio Menna, the FBK-3DOM unit has been active in the context of industrial metrology, collaborating with industrial partners worldwide. The latest 3D active and passive sensors and techniques have been combined and used to measure industrial components, feeding online optimization processes or providing automatic inspection and report for quality control.

Prototype system (left) developed by the 3DOM unit that fuses photogrammetry and photometric stereo techniques for the 3D inspection of industrial components (right).

Lastly, the 3DOM unit is developing innovative methods of inspections that fuse 3D imaging and artificial intelligence with the aim of improving working conditions and reducing the stress related to human-based visual inspection. Indeed, although methods for automatic inspections have significantly evolved over the last few years, still several manufacturing processes rely on human-based visual inspection tasks for quality control.

3D Optical prototype system (left) developed by the FBK-3DOM unit, for the 3D inspection of industrial components and defects (right).

Among the research projects of FBK-3DOM related to industrial metrology we need to mention UPDATE – fast aUtomatic insPection with 3D imAging and arTificial intElligence – financially supported by Fondazione CARITRO and in collaboration with EOPTIS srl.